A question of precision.

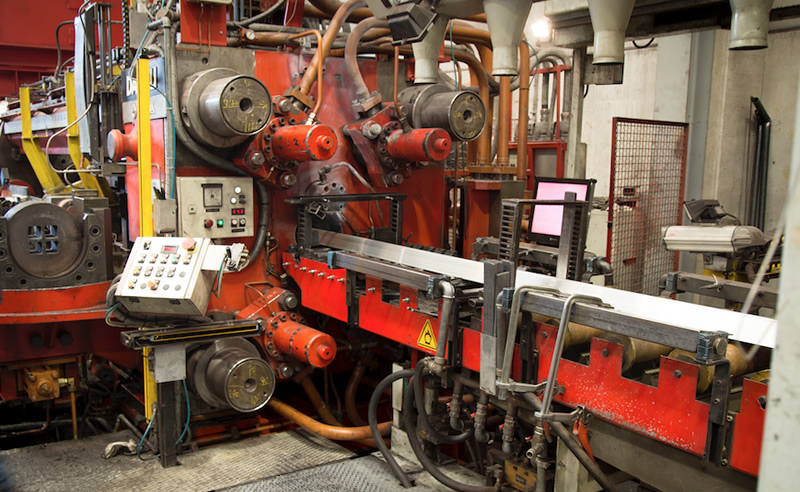

Extrusion is an industrial process that enables aluminium to be compressed in a plastic state, using a mould, in order to obtain constant section bars.

The geometries of tubes and profiles are therefore obtained by constant monitoring of multiple parameters such as temperature, pressure and extrusion speed.

Our mechanical department is continually trained and kept up-to-date with technologies so it can implement systems based on the most innovative techniques, bringing the possibility of errors increasingly close to zero. Gastaldello Sistemi represents the industry's new-generation solutions.

To obtain different types of profile, it is necessary to construct a steel mould, known as a matrix. Our matrices are made based on a profile technical design, the result of a series of in-depth studies aimed at obtaining a final product that can be applied to different sectors.

Gastaldello Sistemi guides the customer towards the best solutions from the point of view of efficiency and technique. Once the matrix has been obtained, it is necessary to equip it to make it suitable for the production of extrusion bars. Equipping it consists of a series of interventions, or corrections. This task is performed by highly specialised workers who use their skills to ensure a perfect match between the bar produced and the design of the desired profile.

The complexity associated with hot extrusion production strongly affects the conformity of the desired product, as well as the removal of the metal mass that drops from 500 degrees centigrade to room temperature. The matrix workshop staff therefore has a huge responsibility in terms of the quality of the end product, which is why our technicians were selected from the most qualified professionals. Finally, the process culminates with the ageing of the product to ensure the aluminium has the mechanical characteristics that are suitable for the customer’s requirements.

Today, our business no longer focusses exclusively on the window sector, but includes all fields in which aluminium is the solution. Thanks to the multiple shapes obtained by the extrusion process and because of its excellent qualities in terms of lightness, versatility, ductility and mechanical performance, aluminium is now used in many aspects of our life.

This unique material has made its entry into the most diverse sectors of industry and construction, where it has been used for a long time. Just think of the range of aluminium used in the construction of aircraft, trains, cars, motorcycles, bicycles, furnishing or lighting, kitchen utensils, technological equipment and other products. So we are talking about an intelligent opportunity for finding new solutions.

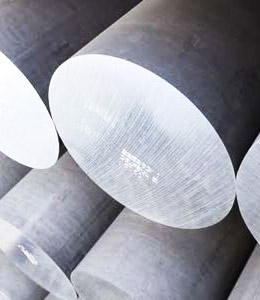

At our extrusion plant, alloy 6060 (F19, F22, F25) is used and various alloys can be extruded on request. T1, T5 and T6 profiles can be obtained in the physical state. The bars can be supplied in length ranging from a minimum of 4,000 mm to a maximum of 7600 mm and profiles of up to 200 mm wide can be extruded. For industrial profiles, additional machining can be requested, such as cutting, drilling, milling and all types of modifications can be made using the most modern and advanced numerically controlled machining techniques.